Every year, perfectly edible food worth millions is tossed from corporate cafeterias and educational institutions across the UK, according to studies. You can picture the daily scenes – piles of sandwiches left untouched, salads untouched, and half-served trays dumped straight into bins. It’s not only about fiscal losses, but also about missed opportunities for happier employees and healthier options. Then AI menu planning for canteens arrived. By leveraging predictive analytics and real-time adjustments, intelligent menu planning software significantly reduces waste. It optimizes appropriate portions instantaneously, adapts recipes, personalizes choices via preferences and allergies, streamlines procurement, and lessens unnecessary emergency orders.

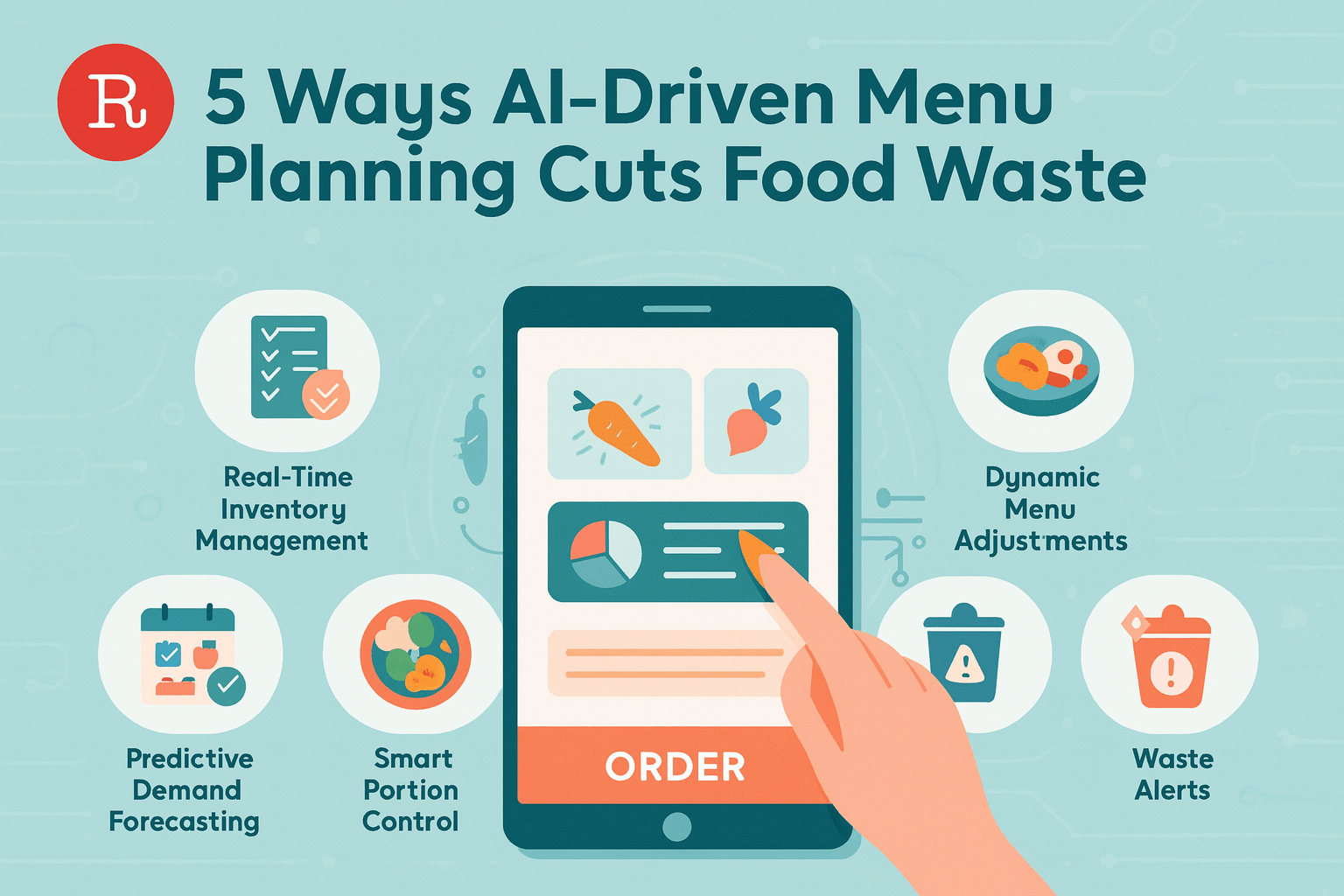

This article explores five key strategies in technology. These include forecasting demand, automated recipe tweaks, filtration by allergies and preferences, just-in-time purchasing, and proven outcomes from pilot programs. AI-driven optimization of food menus isn’t merely forthcoming; numerous companies are already saving thousands in costs and waste using it now.

AI-Driven Canteen Demand Forecasting with Historical Sales Data

Manual spreadsheets and yesterday’s averages cannot keep pace with hybrid work, term timetables, clinics, conferences, or the British weather. Artificial intelligence menu forecasting canteen tools read years of POS history alongside calendars and local signals to predict headcount and dish-level portions accurately. Think of it as a living model of your site that adapts to paydays, exam weeks, payday Fridays, and the first warm day in April.

Start with clean data. Feed the model item-level sales by time slot and station, event calendars from HR and Facilities, term dates or shift rosters, and local weather. The system learns weekly rhythms and seasonal swings, then outputs production plans and purchase lists per service. This directly supports the UK’s policy direction on prevention and resource efficiency.

Accuracy matters because every over-produced tray is pure cost. UK sector evidence shows that prevention delivers outsized savings across hospitality and food service. WRAP’s work quantifies the problem and the upside of acting: UK food waste and food surplus: key facts. A forecasting engine aligned to these aims helps you move from “cook and hope” to “cook to plan.”

Leveraging Historical Data for AI Menu Forecasting

The fastest wins arrive when you connect ai-driven canteen demand forecasting to real operational datasets. POS logs reveal which dishes truly move by day and time. HR calendars explain dips and spikes, from all-hands meetings to off-site training. Universities and trusts can layer in term weeks and clinic schedules. Weather and local events add short-term corrections. Example: last quarter your curry outsold lasagne on Mondays by 18 percent, but only when payday fell within three days. The model learns that pattern and sets next Monday’s production accordingly.

When this loop runs daily, chefs prep to realistic counts. Finance sees fewer write-offs. Diners get fresh food instead of yesterday’s reheats. Forecasting is not an IT project. It is a kitchen project with numbers.

Seasonal Trend Analysis to Prevent Overproduction

Seasonality bites hard in Britain. Warm spells lift salads, wraps, fruit bowls. Cold snaps lift soups, roasts, jacket potatoes. A good model recognises these swings and nudges the menu management plan to match. Tie promotions to the season, not the storeroom. When the engine sees warmer weeks coming, it moves prep from heavy mains to cold stations, which lowers plate waste without shrinking choice. This aligns with industry progress under Courtauld 2030 and the wider prevention agenda.

Machine-Learning Models for Accurate Demand Predictions

Time-series models, gradient boosting and sequence models outperform fixed rules because they “remember” patterns and adjust when behaviour shifts. UK analysis from Deloitte shows predictive analytics and AI can cut waste and improve availability in food service, especially when forecasting is tied to inventory and prep routines. Automated Recipe Adjustment Based on Real-Time Stock Levels

You should not discover at 12:15 that you are short of spinach. Canteen AI menu optimisation software connects recipes to live stock and auto-adjusts batch sizes before the line opens. The goal is tight alignment between what you intend to serve and what is physically on the shelves.

Map every dish to its ingredients, yields, and tolerances. The engine reads stock counts and use-by dates from your inventory system and scales prep lists automatically. Running low on spinach. The system trims each portion by a few grams across the batch or offers a pre-approved swap, such as baby kale. Have chicken close to date. It schedules a grilled option early in the week and pushes beef to later services. Small, invisible changes across hundreds of portions add up to real money.

Integration with Inventory Management & AI Optimisation Tools

Integration is where waste reduction goes from theory to practice. An API pulls counts, batches, and expiry data from stock. The AI pushes scaled recipes, batch sheets, and pick lists back to the kitchen screens. Feedback from waste stations and smart scales makes the loop tighter the next day. The national prevention framework is clear.

Dynamic Recipe Scaling to Optimise Ingredient Usage

Dynamic scaling is not about short-changing diners. It is about using tolerances well. If you are 5 kilograms short on spinach across 100 salads, reduce each portion by 50 grams and add a few grams of another green. Nobody notices, nothing spoils, and your GP stays intact. Ingredient-level optimisation matters in a market where the economic cost of edible food waste is counted in the billions. Use the model to exhaust near-date items first, then build the next day’s mise-en-place around what will actually sell.

AI-Powered Allergy and Preference Filters for Personalised Menus

Food must be safe and relevant. AI menu personalisation for workplace dining ensures each person sees a menu that fits their needs. Profiles hold allergies, preferences and goals. The system hides unsafe items by default, surfaces relevant dishes first, and learns what each diner actually orders.

This is not optional in the UK. Natasha’s Law tightened labelling rules for pre-packed for direct sale foods and raised the bar for allergen transparency. Digital menus that apply the same discipline are a practical line of defence and a trust builder in staff restaurants and student refectories.

Configuring Dietary Restrictions in AI Menu Personalisation

Tag every recipe against the 14 legal allergens, plus lifestyle preferences, faith requirements, and health markers such as reduced sodium. Keep tags in the recipe system, not a side spreadsheet. Let staff set their own profile in the app and sync those preferences via SSO. In education and healthcare, this protects vulnerable diners and reduces clinical risk. In offices, it reduces awkward conversations at the till and increases confidence in the food offer.

Personalised Menu Recommendations with AI Forecasting

Recommendations are only useful when they are accurate. Use order history to suggest variety inside a preference. If Emma tends to choose high-protein salads, surface a new option that fits that pattern. If David selects gluten-free wraps, do not bury them in the carousel. Show them first. This keeps plate waste low, repeat visits high, and supports well-being goals. It also feeds the model more signal, so tomorrow’s recommendations improve again.

Supplier Integration for Just-in-Time Purchasing

Buying for “just in case” creates waste. Buying for “just in time” cuts it. Canteen menu AI integration with HR systems pulls attendance signals from rosters and calendars into the forecast, then raises precise purchase orders through your procurement platform. You get the right volume, on the right day, at the right site.

Connect forecast to procurement. The engine calculates net requirements by ingredient, checks current stock and inbound deliveries, and raises POs for the shortfall. Suppliers confirm against your delivery windows. If headcount drops because of remote days or exams ending, the next run shortens orders automatically. UK policy again supports this prevention-first logic. The government’s waste prevention programme puts the emphasis on avoiding waste, not simply handling it after the fact.

Canteen Menu AI Integration with Procurement Platforms

Choose a platform that can score suppliers by price, lead time, fulfilment rate and sustainability, then route orders intelligently. If cherry tomatoes are scarce, the system either suggests a menu swap or splits the PO across two approved growers. Procurement sees a clean audit trail. Chefs see boxes that actually match the plan.

Benefits of Corporate Canteen Menu Automation with AI

Teams report fewer emergency orders, tighter stock turns, and fewer expired items. WRAP’s national data shows the scale and cost of waste, which is why prevention delivers such strong ROI when you automate purchasing to plan.

30% Waste Reduction: Results from an AI-Based Canteen Menu Scheduling Pilot

A UK multi-site workplace canteen piloted ai-based canteen menu scheduling for eight weeks. The goal was simple. Cut overproduction and align purchasing to realistic demand.

The team connected POS, recipes, allergens, inventory, HR calendars and procurement. They trained chefs to work from prep lists and scaled batch sheets, and they measured outcomes weekly. Results. Monthly food waste dropped from 200 kg to 140 kg, a 30 percent cut. Emergency orders fell from 15 percent to 5 percent of total POs. Procurement savings averaged £2,500 per month at the busiest site. Satisfaction scores rose as diners saw fresher menus matched to the day.

Case Study: AI-Driven Food Menu Optimisation Outcomes

Before AI, production followed a fixed template with top-up batches and frequent leftovers. After AI, the kitchen cooked to a forecast, then adjusted to livestock and attendance changes. Managers saw fewer voids, more consistent GP, and an easier story to tell in ESG reports. These outcomes align with UK analysis showing that predictive analytics and AI reduce waste and improve availability in food service.

Measuring Success: KPIs for Waste Reduction and Cost Savings

Track three layers. Waste, production, and satisfaction. Waste kg per cover by meal period, forecast accuracy by station and dish, emergency orders as a percent of POs, menu match rate on personalised recommendations, and diner uptake and NPS. Put those numbers on a weekly dashboard. To quantify success clearly, the following KPIs were closely monitored:

| KPI | Before AI | After AI | Improvement |

| Monthly Food Waste (kg) | 200 kg | 140 kg | 30% |

| Emergency Orders (%) | 15% | 5% | 66% |

| Monthly Procurement Savings (£) | £0 | £2,500 | Significant |

Best AI Menu Planning Tools for Staff Cafeterias

Shortlist platforms that combine the following. Ai-driven canteen demand forecasting with dish-level outputs. Inventory and waste analytics, ideally with image or scale inputs. Personalised menus with allergy-safe filtering. Procurement automation with supplier scorecards. Clear integrations to POS, HR and finance. Ask vendors to prove measurable waste and cost outcomes at comparable UK sites.

How to Implement AI Menu Planning in a Canteen

- Audit the data. POS history, recipes and allergens, stock files, HR calendars, supplier catalogues.

- Pick a pilot site. Busy service, cooperative chef team, clear baseline.

- Integrate systems. Start with POS and inventory, then add HR and procurement.

- Train the team. Chefs on prep lists and swaps, managers on dashboards, finance on KPIs.

- Target, Measure, Act. Mirror WRAP’s framework. Publish the numbers, then iterate.

Conclusion:

The evidence is clear: an AI menu planning canteen trims waste at every step. Forecast smarter. Scale recipes to stock. Personalise by allergy and taste. Buy only what you need. Then prove the gains with KPIs and reporting. Ready to see it live? Book a RevealMyFood walkthrough and compare your current waste curve to an AI-powered one in weeks, not months.

FAQs

What is AI menu planning for corporate canteens?

It is the use of forecasting, inventory links and personalisation to plan dishes, quantities and purchasing so you produce the right food at the right time with minimal waste.

Does AI forecasting really reduce waste?

Yes. UK analysis and case work show that predictive analytics and AI reduce overproduction and improve availability when tied to inventory and procurement.

How does AI help with allergy compliance?

Menus are tagged to the 14 legal allergens and filtered per user profile to remove unsafe options. This complements PPDS labelling requirements under Natasha’s Law.

Which systems should I integrate first?

Start with POS and inventory, then add HR calendars and procurement. That unlocks forecasting, stock-aware recipes and corporate canteen menu automation with AI.